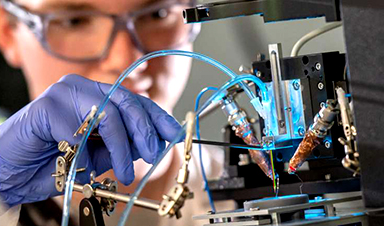

It takes chemist Liaisan Khasanova less than a minute to turn an ordinary silica glass tube into a printing nozzle for a very special 3D printer. The chemist inserts the capillary tube—which is just one millimeter thick—into a blue device, closes the flap and presses a button. After a few seconds there is a loud bang and the nozzle is ready for use.

Khasanova and her colleagues need the minuscule nozzles to print incredibly tiny three-dimensional metallic structures. This means the nozzles’ openings must be equally tiny—in some cases so small that only a single molecule can squeeze through. “We are trying to take 3D printing to its technological limits,” says Dr. Dmitry Momotenko, who leads the junior research group at the Institute of Chemistry. His goal: “We want to assemble objects atom by atom.”

Numerous applications

Nanoscale 3D printing—in other words 3D printing of objects that are a just few billionths of a meter in size—opens up amazing opportunities, the chemist explains. For metal objects in particular, he can envisage numerous applications in areas such as microelectronics, nanorobotics, sensor and battery technology: “Electroconductive materials are needed for all kinds of applications in these areas, so metals are the perfect solution.”

While 3D printing of plastics has already advanced into these nanoscale dimensions, manufacturing tiny metal objects using 3D technology has proven more difficult. With some techniques the printed structures are still a thousand times too large for many advanced applications, while with others it is impossible to fabricate the objects with the necessary degree of purity.

Momotenko specializes in electroplating, a branch of electrochemistry where metal ions suspended in a salt solution are brought into contact with a negatively charged electrode. The positively charged ions combine with electrons to form neutral metal atoms which are deposited on the electrode, forming a solid layer.

“A liquid salt solution becomes a solid metal—a process which we electrochemists can control very effectively,” says Momotenko. This same process is used for chrome-plating car parts and gold-plating jewelry on a larger scale.

A little smaller than usual

However, transferring it to the nanoscopic scale requires considerable ingenuity, effort and care, as a visit to the group’s small laboratory on the university’s Wechloy campus confirms. The lab contains three printers—all built and programmed by the team itself, as Momotenko points out. Like other 3D printers they consist of a print nozzle, tubes for feeding in the print material, a control mechanism and the mechanical components for moving the nozzle—but in these printers everything is a little smaller than usual.

A colored saline solution flows through delicate tubes into the thin capillary tube, which in turn contains a hair-thin piece of wire—the anode. It closes the circuit with the negatively polarized cathode, a gold-plated silicon flake smaller than a fingernail, which is also the surface on which the printing takes place. Micromotors and special crystals that morph instantaneously when an electrical voltage is applied rapidly move the nozzle by fractions of a millimeter in all three spatial directions.

Since even the slightest vibrations can disrupt the printing process, two of the printers are housed in boxes covered in a thick layer of dark-colored acoustic foam. Furthermore, they are resting on granite plates, each weighing 150 kilograms. Both measures are aimed at preventing unwanted vibrations. The lamps in the lab are also battery-powered because the electromagnetic fields produced by alternating current from a socket would interfere with the tiny electrical currents and voltages needed to control the nanoprinting process.

A trip into the nanoworld

Meanwhile, Liaisan Khasanova has prepared everything for a test print: the print nozzle is in its starting position, the box is closed, a vial containing a light blue copper solution is connected to the tubes. She starts a program which initiates the printing process. Measurement data appears on a screen as curves and dots. These show the variations in the current flow and register the nozzle briefly touching the substrate and then retracting again and again. What is the machine printing? “Just a few columns,” she replies.

Columns are the simplest geometric forms generated in 3D printing, but the Oldenburg researchers can also print spirals, rings and all kinds of overhanging structures. The technique can currently be used to print with copper, silver and nickel, as well as nickel-manganese and nickel-cobalt alloys. In some of their experiments, they have already ventured deep into the nanoworld. Momotenko and an international team of researchers reported in a study published in the journal Nano Letters in 2021 that they had produced copper columns with a diameter of just 25 nanometers—taking 3D metal printing below the 100-nanometer limit for the first time.

One of the cornerstones for this success was a feedback mechanism that enables precision control of the print nozzle’s movements. It was developed by Momotenko together with Julian Hengsteler, a Ph.D. student he supervised at his previous place of work, ETH Zurich in Switzerland. “The continuous retraction of the print nozzle is enormously important, because otherwise it would quickly become clogged,” explains the chemist.

“A liquid salt solution becomes a solid metal—a process which we electro-chemists can control very effectively.”

The team prints the tiny objects layer by layer at speeds of a few nanometers per second. Momotenko still finds it amazing that objects too small to be visible to the human eye are being created here. “You start with an object you can touch. Then a certain transformation takes place and you are able to control these invisible things at an extremely small scale—it is almost unbelievable,” says the chemist.

An e-car might be charged within seconds

Momotenko’s plans for his nanoprinting technique are also pretty mind-boggling: his goal is to lay the foundations for batteries that can be charged a thousand times faster than current models. “If that can be achieved, you could charge an e-car within seconds,” he explains. The basic idea he is pursuing is already around 20 years old. The principle is to drastically shorten the pathways of the ions inside the battery during the charging process.

To do this, the electrodes, which are currently flat, would have to have a three-dimensional surface structure. “With the current battery design, charging takes so long because the electrodes are relatively thick and far apart,” Momotenko explains.

The solution, he says, is to interlock the anodes and cathodes like fingers at the nanoscale and reduce the distance between them to just a few nanometers. This would allow the ions to move between anode and cathode at lightning speed. The problem: so far it has not been possible to produce battery structures with the required nano dimensions.

Momotenko has now taken on this challenge. In his NANO-3D-LION project, where the goal is to develop and employ advanced nanoscale 3D printing techniques to fabricate active battery materials with ultrasmall structural features. Having collaborated successfully with a research group led by Prof. Dr. Gunther Wittstock at the Institute of Chemistry in an earlier project, Momotenko then decided to base the project at the University of Oldenburg. “The Department for Research and Transfer was very helpful with my grant application, so I moved here from Zurich at the beginning of 2021,” he explains.

His research group now has four members: besides Khasanova, Ph.D. student Karuna Kanes and Master’s student Simon Sprengel have joined the team. Kanes focuses on a new method aimed at optimizing the precision of the print nozzle, while Sprengel investigates the possibility of printing combinations of two different metals—a process necessary to produce cathode and anode material simultaneously in one step.

Liaisan Khasanova will soon focus on lithium compounds. Her mission will be to find out how the electrode materials currently used in lithium batteries can be structured using 3D printing. The team is planning to investigate compounds such as lithium-iron or lithium-tin, and then to test how large the nano “fingers” on the electrode surfaces need to be, what spacing is feasible, and how the electrodes should be aligned.

Handling highy reactive lithium

One major hurdle here is that lithium compounds are highly reactive and can only be handled under controlled conditions. For this reason, the team recently acquired an extra-large version of a laboratory glove box, a gas-tight sealed chamber that can be filled with an inert gas such as argon. It has handling gloves built into one side with which the researchers can manipulate the objects inside.

The chamber, which is about three meters long and weighs half a ton, is not yet in operation, but the team plans to set up another printer inside it. “The chemical conversion of the material and all other tests will also have to be carried out inside the chamber,” Momotenko explains.

The team will run up against some major questions in the course of the project: How do tiny impurities within the argon atmosphere affect the printed lithium nanostructures? How to dissipate the heat that is inevitably generated when batteries are charged within seconds? How to print not just tiny battery cells but also large batteries for powering a mobile phone or even a car—within a reasonable time?

“On the one hand, we are working on the chemistry needed to produce active electrode materials at the nanoscale; on the other, we are trying to adapt the printing technology to these materials,” says Momotenko, outlining the current challenges.

The problem of energy storage is extremely complex, and his team can only play a small part in solving it, the researcher emphasizes. Nonetheless, he sees his group in a good starting position: in his opinion, electrochemical 3D printing of metals is currently the only viable option for manufacturing nanostructured electrodes and testing the concept.

In addition to battery technology, the chemist is also working on other bold concepts. He wants to use his printing technique to produce metal structures that allow for a more targeted control of chemical reactions than possible so far. Such plans play a role in a relatively young field of research known as spintronics, which focuses on the manipulation of “spin”—a quantum mechanical property of electrons.

Another idea he hopes to put into practice is to manufacture sensors that are able to detect individual molecules. “That would be helpful in medicine, for detecting tumor markers or biomarkers for Alzheimer’s at extremely low concentrations, for example,” says Momotenko.

All these ideas are still very new approaches in chemistry. “It is not yet clear how it would all work,” he admits. But that’s how it is in science: “Every meaningful research project requires long thinking and planning, and in the end most ideas fail,” he concludes. But sometimes they don’t—and he and his team have already taken the first successful steps on their journey.

News

Shocking Amounts of Microplastics in the Brain – It Could Be Increasing Our Risk of Dementia

The brain has higher concentrations of plastic particles compared to other organs, with increased levels found in dementia patients. In a comprehensive commentary published in Brain Medicine, researchers highlight alarming new evidence of microplastic accumulation [...]

Baffling Scientists for Centuries: New Study Unravels Mystery of Static Electricity

ISTA physicists demonstrate that contact electrification depends on the contact history of materials. For centuries, static electricity has intrigued and perplexed scientists. Now, researchers from the Waitukaitis group at the Institute of Science and [...]

Tumor “Stickiness” – Scientists Develop Potential New Way To Predict Cancer’s Spread

UC San Diego researchers have developed a device that predicts breast cancer aggressiveness by measuring tumor cell adhesion. Weakly adherent cells indicate a higher risk of metastasis, especially in early-stage DCIS. This innovation could [...]

Scientists Just Watched Atoms Move for the First Time Using AI

Scientists have developed a groundbreaking AI-driven technique that reveals the hidden movements of nanoparticles, essential in materials science, pharmaceuticals, and electronics. By integrating artificial intelligence with electron microscopy, researchers can now visualize atomic-level changes that were [...]

Scientists Sound Alarm: “Safe” Antibiotic Has Led to an Almost Untreatable Superbug

A recent study reveals that an antibiotic used for liver disease patients may increase their risk of contracting a dangerous superbug. An international team of researchers has discovered that rifaximin, a commonly prescribed antibiotic [...]

Scientists Discover Natural Compound That Stops Cancer Progression

A discovery led by OHSU was made possible by years of study conducted by University of Portland undergraduates. Scientists have discovered a natural compound that can halt a key process involved in the progression [...]

Scientists Just Discovered an RNA That Repairs DNA Damage – And It’s a Game-Changer

Our DNA is constantly under threat — from cell division errors to external factors like sunlight and smoking. Fortunately, cells have intricate repair mechanisms to counteract this damage. Scientists have uncovered a surprising role played by [...]

What Scientists Just Discovered About COVID-19’s Hidden Death Toll

COVID-19 didn’t just claim lives directly—it reshaped mortality patterns worldwide. A major international study found that life expectancy plummeted across most of the 24 analyzed countries, with additional deaths from cardiovascular disease, substance abuse, and mental [...]

Self-Propelled Nanoparticles Improve Immunotherapy for Non-Invasive Bladder Cancer

A study led by Pohang University of Science and Technology (POSTECH) and the Institute for Bioengineering of Catalonia (IBEC) in South Korea details the creation of urea-powered nanomotors that enhance immunotherapy for bladder cancer. The nanomotors [...]

Scientists Develop New System That Produces Drinking Water From Thin Air

UT Austin researchers have developed a biodegradable, biomass-based hydrogel that efficiently extracts drinkable water from the air, offering a scalable, sustainable solution for water access in off-grid communities, emergency relief, and agriculture. Discarded food [...]

AI Unveils Hidden Nanoparticles – A Breakthrough in Early Disease Detection

Deep Nanometry (DNM) is an innovative technique combining high-speed optical detection with AI-driven noise reduction, allowing researchers to find rare nanoparticles like extracellular vesicles (EVs). Since EVs play a role in disease detection, DNM [...]

Inhalable nanoparticles could help treat chronic lung disease

Nanoparticles designed to release antibiotics deep inside the lungs reduced inflammation and improved lung function in mice with symptoms of chronic obstructive pulmonary disease By Grace Wade Delivering medication to the lungs with inhalable nanoparticles [...]

New MRI Study Uncovers Hidden Lung Abnormalities in Children With Long COVID

Long COVID is more than just lingering symptoms—it may have a hidden biological basis that standard medical tests fail to detect. A groundbreaking study using advanced MRI technology has uncovered significant lung abnormalities in [...]

AI Struggles with Abstract Thought: Study Reveals GPT-4’s Limits

While GPT-4 performs well in structured reasoning tasks, a new study shows that its ability to adapt to variations is weak—suggesting AI still lacks true abstract understanding and flexibility in decision-making. Artificial Intelligence (AI), [...]

Turning Off Nerve Signals: Scientists Develop Promising New Pancreatic Cancer Treatment

Pancreatic cancer reprograms nerve cells to fuel its growth, but blocking these connections can shrink tumors and boost treatment effectiveness. Pancreatic cancer is closely linked to the nervous system, according to researchers from the [...]

New human antibody shows promise for Ebola virus treatment

New research led by scientists at La Jolla Institute for Immunology (LJI) reveals the workings of a human antibody called mAb 3A6, which may prove to be an important component for Ebola virus therapeutics. [...]